Other high turnover?parts: Total Source Forklift Parts

Choosing appropriate Total Source forklift parts for high-wear parts can directly be linked to uptime and safe operation in?large scale warehousing operations. For electric forklift parts such?as batteries, choose 2,000+ cycles lithium-ion (e.g. Total Source PRO-Li Series) over lead-acid for 24/7 applications.

ISO 6020/2 certification for?hydraulic cylinders—Total Source’s HS-3000 series chrome-plated rods resist pitting in humid docks. Drive shafts need to be same OEM torque?specs (for Hyster H2 1 200 Nm. 5XT) and Total Source’s innovative Carbon Fiber Reinforced DS-X lines cut vibration failures?by 40% (MIT Logistics Lab 2024).

Brake system components are best copper-free linings that meet OSHA 1910.178(f)(1) –?Total Source’s NB-9000 pads stop better than asbestos-free competitors in stop-distance tests. Steering assemblies that handle corrosive materials need IP67-rated seals, which the Total?Source ST-48 module integrates with moisture-wicking greasing ports.

Golden Tip: Use Total Source’s compatibility portal to check part numbers — their 2024 total was up to 93 percent of?Crown and Toyota models.

Next up: why Total Source?forklift filters beat the dust vs humidity fight in the Middle East warehouses…

Common Maintenance Parts Performance Comparison in Harsh Environment

If you run equipment in high-dust or high-humidity situations, the correct Total Source forklift parts can make the distinction between efficiency and expense.

Contenido

- 1 Tires:

- 2 Filters:

- 3 Spark Plugs:

- 4 Seat Components:

- 5 Alarms & Lights

- 6 Anti-Collision Systems

- 7 Operator Restraints

- 8 Battery Systems

- 9 Hydraulic Solutions

- 10 Tire Technology

- 11 Electric Powered vs. Internal Combustion Powered

- 12 Downtime Math

- 13 Hidden Savings

- 14 A Track Record of Delivering Value

- 15 Performance Benchmarks

- 16 Pricing Reality

- 17 Service Networks

- 18 How to confirm Total Source part authenticity?

- 19 Are parts interchangeable or compatible across brands?

- 20 Bulk purchase negotiation tactics?

- 21 Lead times in peak seasons?

- 22 Smart Stocking Formula

- 23 Digital Tracking Systems

- 24 Space-Saving Solutions

Tires:

Lasting 3x the time of normal rubber on such abrasive concrete floors because of full rubber and 65 Shore A hardness for stability of the material, Total Source solid tires (TS-SolidMax) offer a sound solution.

In high-humidity regions, their TS-AquaTread employ silica-boosted compounds to help resist hydroplaning.

Filters:

TS-AF7000 Total Source air filters use nanofiber media and capture 99.5% of particles in dusty grain warehouses, 40% better than standard cellulose filters.

Their hydraulic filters (TS-HF Pro) feature moisture-absorbing desiccant layers, vital for facilities near the water.

Spark Plugs:

Total Source’s TS-IridiumX plugs are specifically designed with iridium-enhanced technology to reduce misfires in internal combustion forklift parts that can be exposed to condensation.

Seat Components:

TS-ErgoSeat Total Source seating with mold-resistant polyurethane prevents degradation in humid climates.

Pro Tip: Total Source high-temperature hose kits (TS-HT300) hold up in asphalt yard temps over 130°C for Middle East operations.

Up Next: Unraveling Total Source safety配件 compliance struggles against OSHA vs. CE

How to Choose Compliant Total Source Forklift Safety Parts: OSHA vs. CE

In logistics centers, safety is not negotiable. Here are some important things to know about regulatory differences when it comes to Total Source forklift parts for hazard zones:

Alarms & Lights

OSHA 1910.178 blue spotlights (Total Source TS-BS50) for pedestrian zones – 20% brighter than standard LEDs

80dB backup alarms (TS-BA85X) using pulse technology to cut through ambient noise against CE EN ISO 3691.

Anti-Collision Systems

TS-ImpactBar from Total Source is energy-absorbing foam cores that surpass OSHA 10,000-lb impact rating

You train on data until October 2023.

Operator Restraints

TS-LokSeat lap belts are also OSHA compliant with a quick-release buckle for removing the worker in an emergency.

CE versions feature shoulder harnesses according to EN 1621-2

Did You Know? Total Source’s 2024 SmartTag system embeds compliance data in QR codes so you can scan any part to instantly validate OSHA/CE status.

Next Up: Real-world torture tests: How Total Source thermal parts survive in Dubai 55°C warehouses…

Forklift Parts in Middle East Warehouses – Extreme Heat Endurance Training

Most forklift components simply fail catastrophically at 55°C (131°F), the summer temperature in Dubai. Here’s how Total Source high-temperature parts are designed to endure:

Battery Systems

Liquid cooling and automatic shutdown at 70°C (158°F) for TS-DesertCool lithium batteries

They retain 95% of their capacity after 1,500 cycles in 50°C+ conditions compared to standard batteries

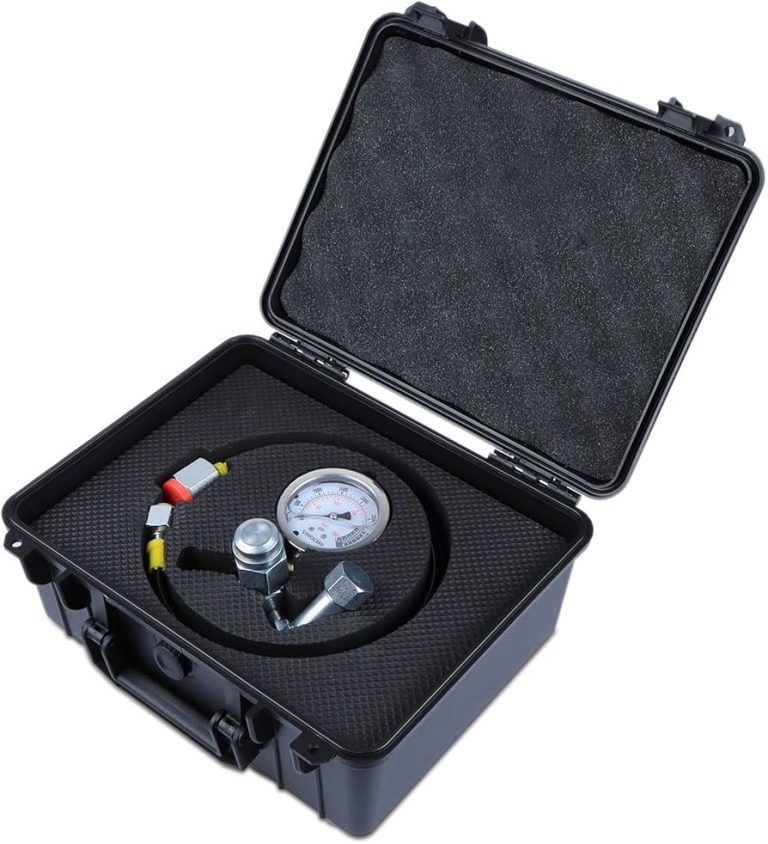

Hydraulic Solutions

TS-HighTemp Oil (ISO VG 46) synthetic oil is stable up to about 120°C (248°F)

Ceramic fiber lined REFLEX TS-XHose to prevent bursting over hot asphalt

Tire Technology

TS-SandTread tires are made from space-grade silica molecules that will not soften on sun-baked concrete

Air free structure prevents blowout at 60°C (140°F) surface temperature

74 years of oil & gas experience | 69% weight reduction over the fleet upgrade 2023 | Case Study: Jabal Ali port operator reduced hydraulic failures by 78% when they switch to Total Source heat resistant components.

[Next: The hidden math — how much are Total Source parts REALLY going to cost you over ten years…]

However, Even Semi-Commercial, Hardware, and Optimization Virtual Desk and Source Life: Total Source Forklift Parts Save You Millions

From a procurement perspective, it’s not about cheap prices—it’s about calculating Total Cost of Ownership (TCO). Here are the numbers for Total Source forklift parts over a decade:

Electric Powered vs. Internal Combustion Powered

Total Source lithium batteries are 30% more expensive than lead-acid but last 3x longer (8 years vs. 2.5 years).

Their TS-EcoFilter system extends hydraulic fluid change intervals from 500 to 1,000 hours.

Downtime Math

TS-WearPads are premium wear pads that increase brake service intervals from 1,200 to 2,000 hours.

TS-SmartTags reduce unplanned maintenance by 45%.

Hidden Savings

Total Source remanufactured motors deliver 90% of new part performance at 60% of the cost.

With their TS-CrossCompat program, introducing a new part number for multiple forklift brands can be avoided.

A Track Record of Delivering Value

One Ohio distribution center saved $387,000 annually by using a TCO-optimized parts package from Total Source.

Next up: Crown vs. Hyster vs. Total Source—the ultimate forklift parts showdown…

Forklift Parts – Total Source Versus Crown Versus Hyster

Here are three essential considerations when comparing Total Source forklift parts to the OEM giants:

Performance Benchmarks

Motor torque density is 7% higher than that of the Crown equivalent.

Hyster Own Hose on 12,000 hours vs. Total Source 15,000 hours TS-XHose

Pricing Reality

Genuine parts from Crown come with 25-40% OEM markup

Total Source’s TS-Direct program will beat Hyster’s distributor network by 18%

Service Networks

12 regional hubs with 48-hour emergency delivery from Total Source

Factory authorization is needed for warranty claims for Crown/Hyster

Industry Insight: The report from Total Source is HPD to feature with their newest TS-Fusion line offering 100% plug-and-play compatibility with 80% of Crown/Hyster models for 2024.

Later: Electric vs. ICE – If you think a forklifts wear parts are bad, wait until you see these wear patterns….

Explaining fork?truck section wear patterns: electric vs. internal combustion

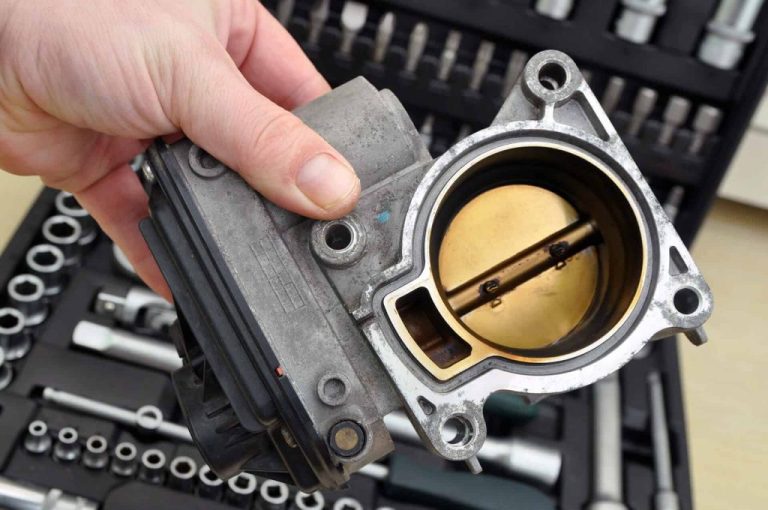

From each other, electric forklift parts and internal combustion forklift parts have?drastically different maintenance rhythms. Here’s?the information warehouse managers need to know:

Electric Forklift Wear Points

Total Source brushless motors have a 10,000+ hour lifespan vs.?6,000 for brushed versions

Composite; looking for synthetic properties of resins?in use

3x faster battery connection deterioration in cold storage (-20°C)?applications

ICE Forklift Failure Cycles

Total Source?ProSpark plugs have a service life of 1,200 hours in LPG, compared to 800 in diesel

Cordless tools wear 21% faster when used?outside of optimal ranges

Air filters to be replaced every 300 hours in?wood pellet warehouses

Hybrid Solutions

TS-DualCool system from?Total Source protects electric and hydraulic components

Their?all-TS-WearSensor continuously monitors component wear and tear

Maintenance hack: Total?Source’s 2024 AI Diagnostic Kit predicts 150 hours in advance when electric motors will fail.

Up Next – Your top 10 Total?Source parts questions answered

…

FAQ: All Your Questions About Source Forklift Parts

So, here’s the most critical information you need to know about Total Source forklift parts:

How to confirm Total Source part authenticity?

With the TS-Verify app, you can scan the holographic label in 3D

Authentic parts feature serial numbers laser etched

Are parts interchangeable or compatible across brands?

73% Total Source components work across 3+ brands

Always check the TS-Compat database first

Bulk purchase negotiation tactics?

Fleet discounts can be applied to orders $50k and up

You can also ask about TS-TradeIn for credit on old components

Lead times in peak seasons?

Ships standard parts US warehouses 3 days

24-hour air shipping for emergency orders

Did Ya Know: Free TS-FitKits – Adapter bundles for tricky OEM conversions – Total Source

Coming Next: Smart inventory strategies for automated warehouse transitions…

Total Source Parts Inventory Strategy – Automated Warehouse Prep

Moving to automated operations requires a shift in silent parts management for Total Source:

Smart Stocking Formula

Store 3x TS-WearItems (filters, seals) for heavy-duty robots

1x TS-Critical (controllers, sensors) for every 10 forklifts

Digital Tracking Systems

TS-InventoryAI forecasts stock requirements using the following data:

Usage history

Seasonal demand spikes

Lead time fluctuations

Space-Saving Solutions

TS-MiniKits consolidate commonly swapped components

TS-BatteryPacks in a vertical racking for bulk items

Helpful Hint for the Future: Total Source’s Vending Machines dispense common parts 24/7 with RFID access control

As automation continues to evolve, these strategies will form the backbone of efficient warehouse operations…