Decades of data collection and its Safety certification policies were recognized as second to none. Since the transmission case houses all of the components inside the transmission system, a crack within the case can lead to symptoms that range from fluid leaks to total transmission failure. A cautious approach to fixing a cracked transmission case is important, so we recommend not damaging the machinery. This guide outlines the steps involved with case repair, walks you through the process, and highlights what you need to know to help make sure you can keep your equipment dependable.

Contents

- 1 Table of Contents:

- 2 The Transmission Case: What the Case Actually Is and Why It Matters

- 3 How to Tell If You Have a Cracked Transmission Case

- 4 Preparing for the Repair

- 5 How to Repair a Cracked Transmission Case

- 5.1 Step 1 — Safety Precautions

- 5.2 Step 2 — Drain the Transmission Fluid

- 5.3 Step 3 — Remove the Transmission Case

- 5.4 Step 4 — Evaluate the Crack

- 5.5 Step 5 — Surface Cleaning and Preparation

- 5.6 Step 6 — Welding the Crack, Side 1

- 5.7 Step 7 — Reassembling the Transmission

- 5.8 Step 8 — Testing the Repair

- 6 Use the Right Assortment for the Right Job

- 7 When to Seek Professional Help

- 8 Preventing Future Fractures in the Transmission Case

- 9 Conclusion

Table of Contents:

- The Transmission Case: What the Case Actually Is and Why It Matters

- Diagnosing a Cracked Transmission Case

- Preparing for the Repair

- How to Repair a Cracked Transmission Case

- Use the Right Assortment for the Right Job

- When to Seek Professional Help

- Preventing Future Fractures in the Transmission Case

- Conclusion

The Transmission Case: What the Case Actually Is and Why It Matters

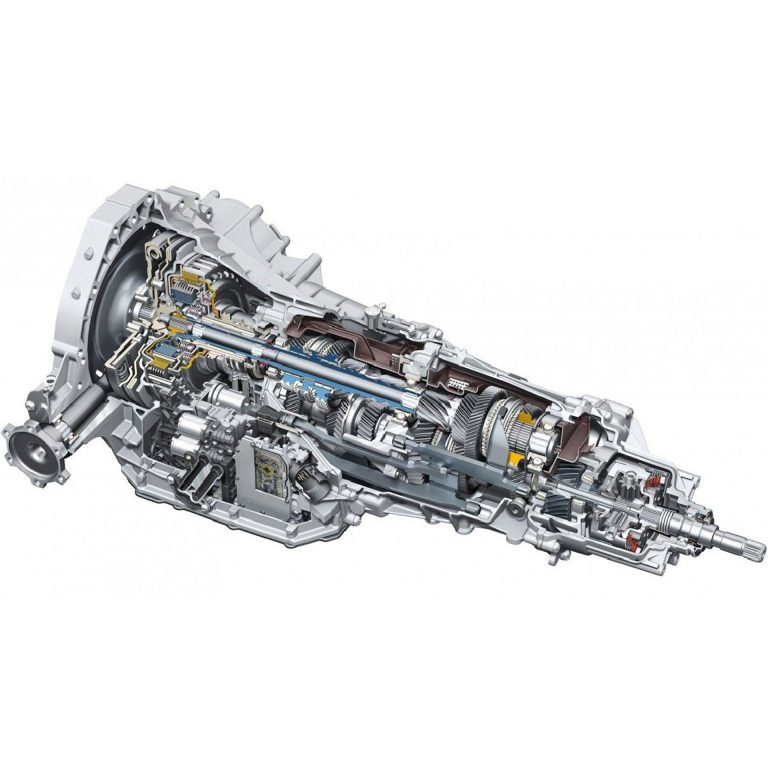

All heavy machinery, such as forklifts and reach stackers are equipped with transmission cases. Gears, bearings, and seals are some of the key transmission parts that it houses. All of these components work in tandem to transfer power from the engine directly to the wheels — making the car operate and powering the machinery.

The transmission may collapse on itself, and the fluid will leak, which may cause the transmission not just to work and finally can make some other cases. Hence, as one of the most common problems, if you discover a cracked transmission case, get it repaired immediately to avoid expensive repair bills or a complete replacement of the transmissions.

How to Tell If You Have a Cracked Transmission Case

A broken transmission case is mostly diagnosed by observing the fluid leaks, strange noise at this stage, and a decline in the working of the transmission. These symptoms may present themselves if you identify a crack:

- Fluid Leaks: There will be a buildup of transmission fluid underneath the machinery indicating a potential case crack.

- Weird Noise: A grinding, whining, or otherwise weird noise from your transmission (especially when under load) can indicate something is going wrong.

- Power Loss: If you have to struggle to change gears, or the vehicle doesn’t respond properly, then there is some internal transmission damage.

You can do this by visually inspecting the transmission case for an exterior fracture or indication of a crack. You could also do a dye penetrant inspect or an internal pressure test for evidence of cracking.

Preparing for the Repair

Repair Process: Collect Proper Tools and Materials First. Essential tools as listed, some of the essential tools are:

- Personal protective equipment: Gloves, safety glasses, and protective clothing.

- Welding machine: To repair larger cracks.

- Transmission fluid: For replenishment post-repair.

- Torque wrench: For reassembling the components with the appropriate tension.

- Gasket material: Used during reassembly to replace seals and gaskets.

In addition, have the manufacturer’s service manual or documentation for the transmission model which is being repaired. Refer to the service manual for important details on torque specs and assembly processes.

How to Repair a Cracked Transmission Case

Step 1 — Safety Precautions

Be sure that the machine is powered off and cooled down first. Tow in put out the parking brake and park the kit on a horizontal and leveled surface. Use Safety Equipment.

Step 2 — Drain the Transmission Fluid

Before removing the transmission case, you must drain the transmission fluid so it doesn’t spill because you don’t want to contaminate the working place. Draining out of the case, open the drain plug. It also makes it possible to pull the transmission case without leaking fluid.

Image: Transmission fluid draining from the case.

Step 3 — Remove the Transmission Case

Uncouple the transmission from the rest of the powertrain. To access the transmission case, you may need to take out other systems from the machinery based on your model, including the drive shaft or engine components. Unscrew the transmission case bolts and lay them in a tray.

Step 4 — Evaluate the Crack

Once the transmission case is removed, assess the crack. This is the length and width that measures how serious it is. In the case of a crack that is too deep or too large to repair with epoxy, the entire case would need to be replaced. But minor cracks or fractures are usually repairable.

Step 5 — Surface Cleaning and Preparation

Clean the area around the crack thoroughly with a degreaser or solvent. That way, the welding material bonds properly to the surface. Cleaning any grime, oil, or other debris makes the effort to repair easier.

Step 6 — Welding the Crack, Side 1

Commonly, you need to use MIG welding (Metal Inert Gas) or TIG welding (Tungsten Inert Gas) when the crack can be repaired. You should be able to weld this safely and without heat damage to the case. Do not burn it out more than it could already be damaged! Weld it and allow the case to cool down prior to the next move.

Image Suggestion: Make a picture of a weld on the transmission case.

Step 7 — Reassembling the Transmission

Once the crack has been repaired, reassemble the elements that form the transmission. Be sure to replace any worn or damaged seals, gaskets, or O-rings. Torquing bolts with a torque wrench, and secure everything to the manufacturer’s specifications.

Step 8 — Testing the Repair

After reassembling the transmission, fill the case with fresh transmission fluid. The more you have on your gear, start the machinery, leak watch, unusual behavior — check it by cycling through and watching the levels. A good repair indicates that the transmission is operating properly and no leaks should be found.

Use the Right Assortment for the Right Job

When it comes to a cracked transmission case, it is vital that you choose superior materials that are going to lead to a heavy-duty patch-up job. When welding, it is advisable to use high-tensile welding rods or wire — for aluminum or steel (depending on what your transmission case is made of). When replacing gaskets, seals, and O-rings, you should always use OEM (Original Equipment Manufacturer) parts.

When to Seek Professional Help

A broken transmission case can be repaired by professional machine operators, but it is worth knowing when to call a professional. And if it is a major crack or in an awkward spot or you’re just not confident with the weld, professional guidance is always advisable. Likewise, if the damage is significant or the case for the transmission is damaged, then replacement is a better option.

Preventing Future Fractures in the Transmission Case

Preventative maintenance is needed to extend the life of the transmission case. Frequent transmission checks are crucial to catch if there is wear and tear, and keep the fluid levels in check to spot leaks in good time. Ensure that it is lubricated and free from wear and tear.

Here at Ningbo Beilun Zhenke we are specialized in and stock various reputable transmission parts and accessories to ensure that is exactly what you do; keeping your essential components serviced, replacing, and maintaining in a timely fashion, so you do not find yourself at another issue.

Conclusion

Cleaning a damaged transmission case is time-consuming and meticulous work. If you know the best methods to follow, the right materials to use, and the solutions to examination, you will be able to methodically get your machine up and running again and save you a few pennies in the process. Machine parts & Midlands construction parts & machine components & machinery components & construction parts & machinery service provider.

Contact Us today if you are interested in transmission components or need to purchase original parts to use in your equipment!

How to feel about it: Add a photo, complete photo of a reassembled running transmission assembly, highlighting the repaired housing.